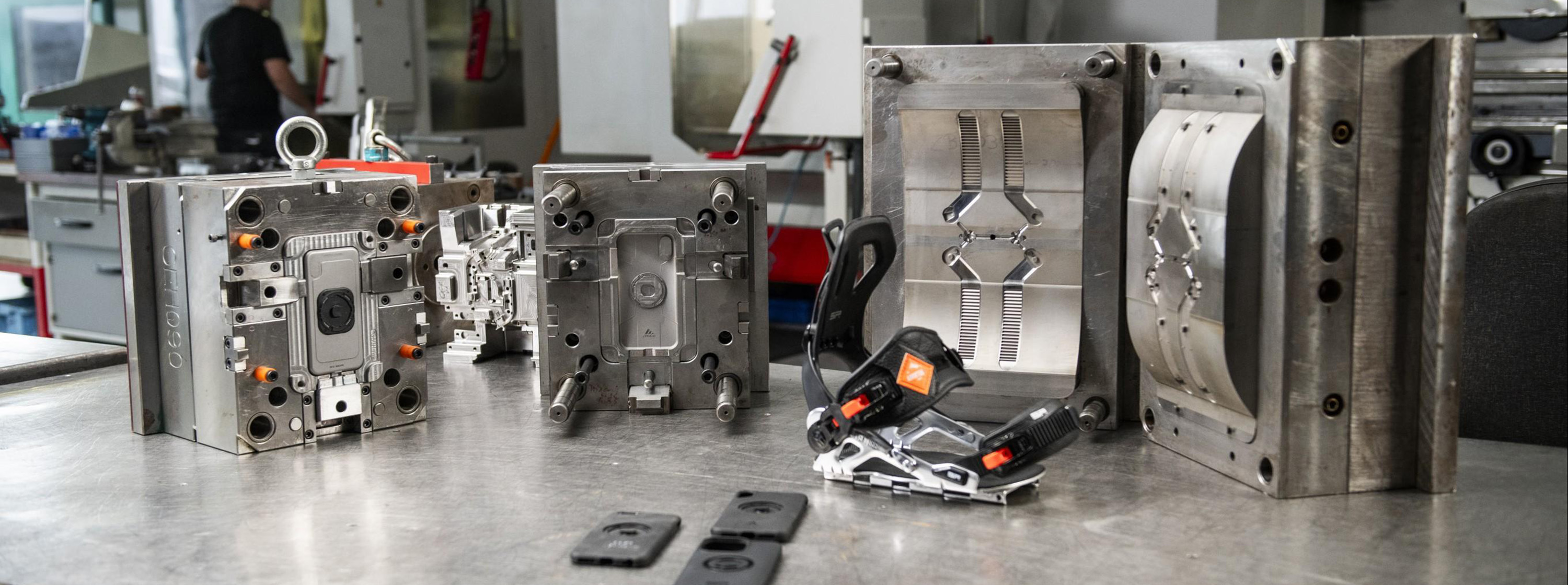

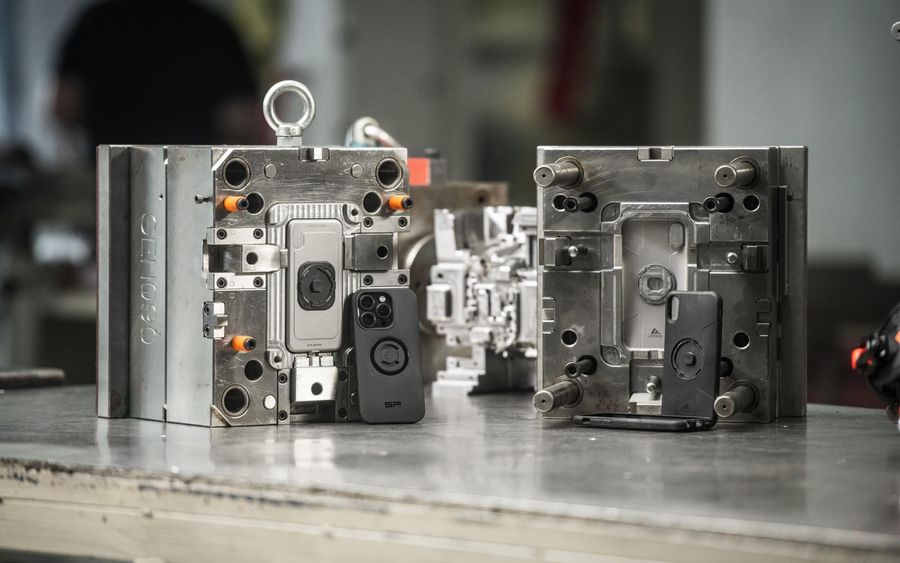

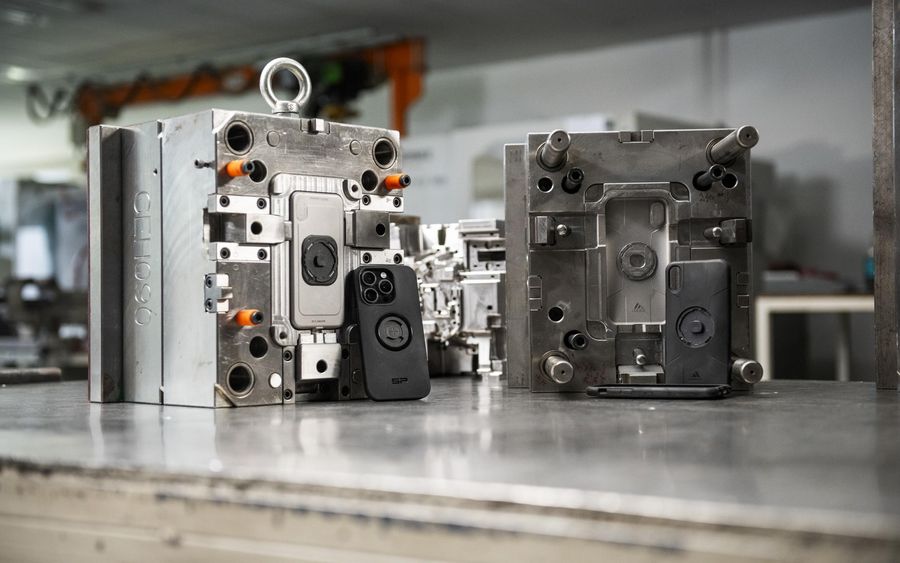

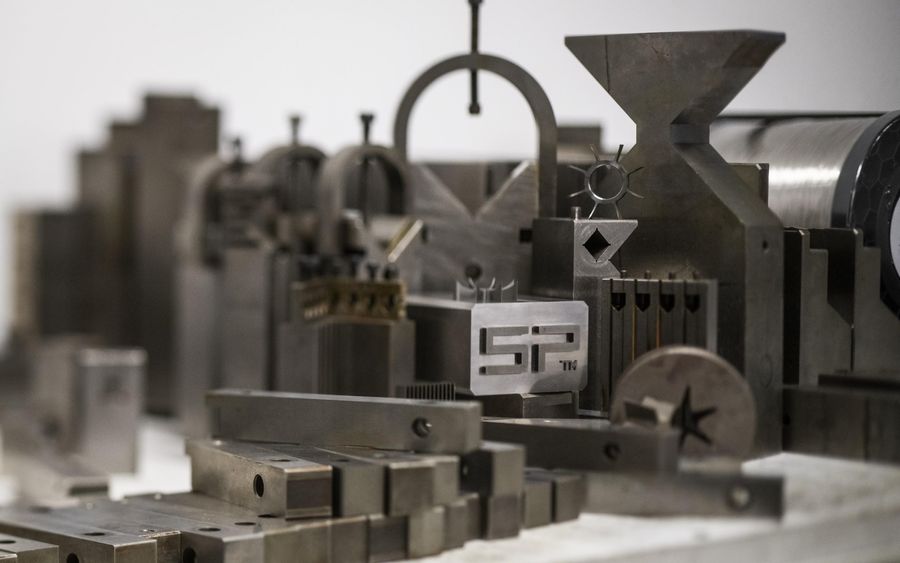

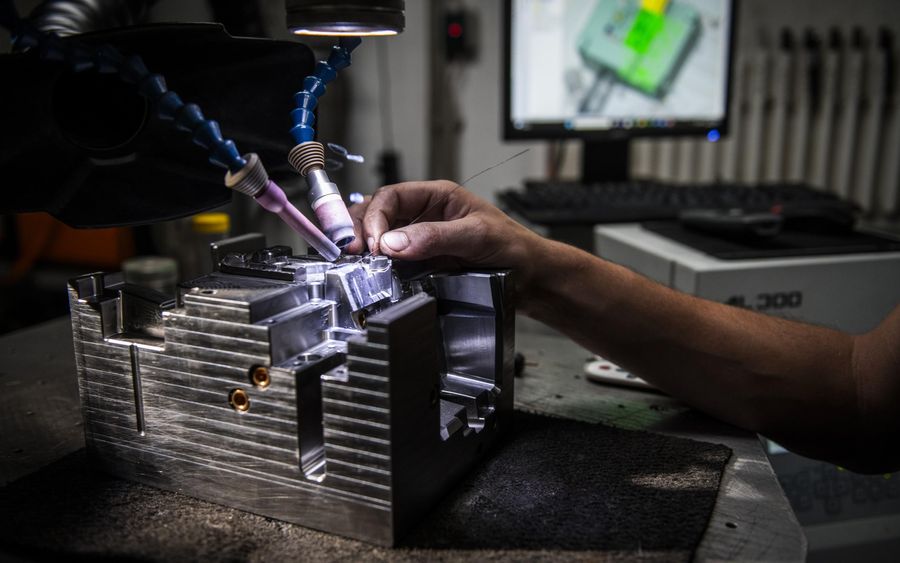

In order to meet the high demands of practical use, we offer expert advice in cooperation with your design and development department.

In addition to designing your tool, we will of course also advise you on the selection of the most suitable material and the optimal tool design. We believe that close cooperation with our customers is the basis for ensuring that our plastic components interact perfectly with the other product components in terms of load-bearing capacity and functionality.